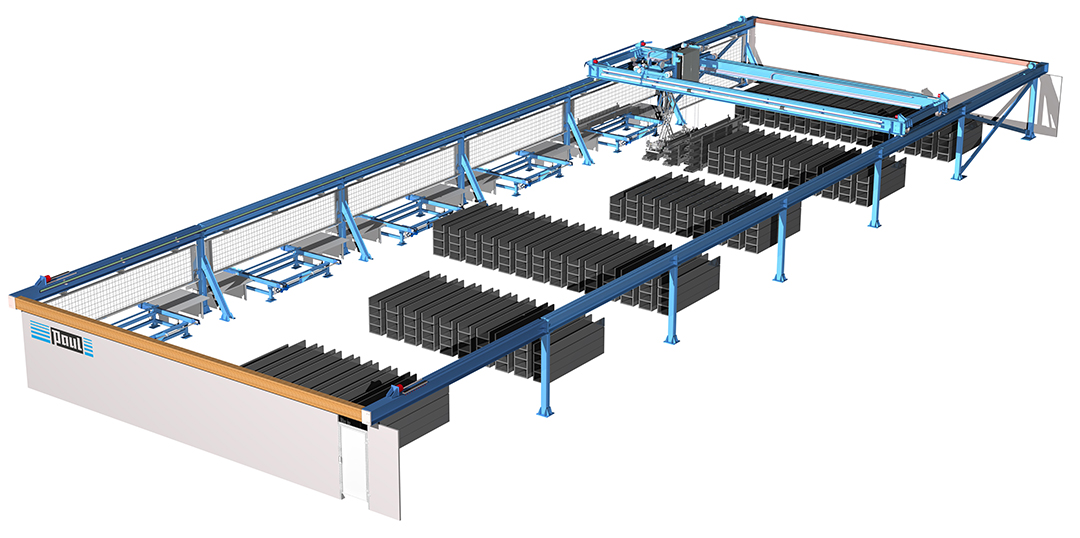

With the Opti-Store storage system, the number of columns and rows may be adapted flexibly.

With the Opti-Store storage system, the number of columns and rows may be adapted flexibly.

PAUL combines modern saw technology with smart material storage solutions. The southern German machine manufacturer has recently adapted its fully automated storage system Opti-Store to meet the customer-specific requirements of a sawmill. Smart and functional storage systems featuring an ideally harmonized control technology are indispensable for the success and economic viability of manufacturing companies in the woodworking industry. They ensure that companies with manifold product ranges do not lose track.

Dried and edged raw material with a length of up to six meters is stored in PAUL Opti-Store containers. These containers are stacked within the storage area in a fully automated manner; with regard to the present application, this comprises a width of three columns, a length of 18 rows and several layers in height. In close coordination between PAUL and the customer, the number of storing places can be adapted individually to the storage area available. This allows to integrate Opti-Store into any available storage area, even retroactively, using spaces in the most optimal way.

During the storage process, the operator will register the raw material and sort it into the containers, for example, by type of wood, dimensions or length. It is also possible that suppliers will deliver their products already stored in containers or that the containers will be filled during upstream processes. Incoming goods will be registered by means of a barcode, which allows the operator to keep track of product availability and storage utilization at any time. The computer-operated crane will collect the container at the transfer gate and then store and stack it wherever space is available at this moment. This dynamic storage system aims at allocating the storage places in a manner that raw material can be stored and released as fast as possible. If needed, the crane will be able to take the material and deliver it to the transfer gate, where the operator will take one part of the pieces or all of them out of the container, restoring the unneeded pieces where required. The number and location of the gates can be defined with regard to customer requirements and local conditions. Connecting Opti-Store to an ERP system allows for further options of fully automated and flexible production processes.

The considered customer expects for its sawmill a number of advantages from the Opti-Store storage system: the company will maintain an overview on its manifold range of planed and profiled workpieces of different lengths. The storage of the workpieces is realized in an ideally space-saving manner, as the area available is used only for storage purposes and not for transportation. When purchasing this economical system, cost-extensive shelves are no longer required since the containers are stacked on top of each other. Occupational safety will be enhanced as the operators will no longer need to stay inside the storage room. The company can flexibly integrate the storage system into its productions processes, while enhancing its performance and capacities at the same time.

Due to Opti-Store’s ability to perfectly adapt to customer-specific demands, further application scenarios are possible.