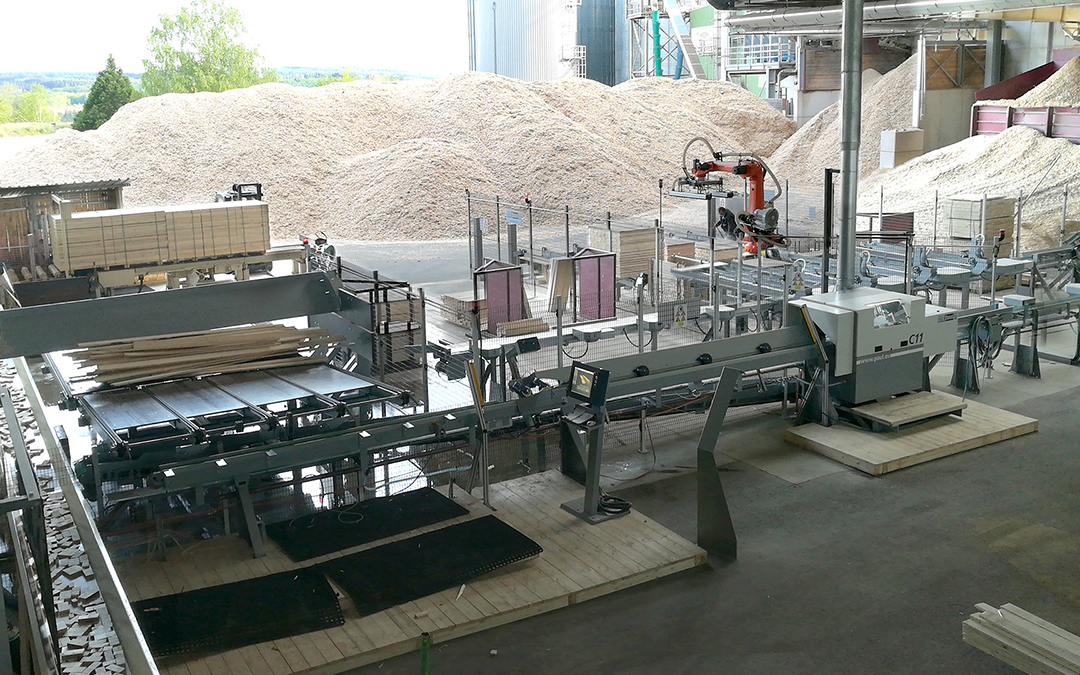

Overview of the system at the customer's factory.

Overview of the system at the customer's factory.

The company Westerwälder Holzpellets GmbH has optimized its sustainability concept. With a fully automatic cross-cut system from Paul, in the future, the company will make pallets from unsaleable boards that do not meet the requirements for the production of high-quality packaging. Such boards have not been thrown away in the past either; instead, they have been used in pellet production. With the new system, they now want to get more out of a faulty board.

The search for a suitable partner to achieve this goal led Westerwälder to Ligna, where contact was made with the Swabian mechanical engineering company Paul. Various planning discussions between the teams of both companies followed until an innovative concept was available. Essentially, the aim is to remove low-quality boards from the main process of an edging and sorting line and to continue using them as efficiently as possible. From this, Westerwälder now produces pallet material of 800 to 1200 mm in length or finger-jointing material. A system operator marks unusable defects in the timber with fluorescent lines, which are then detected by the measuring station and cut out by a C11 cross-cut system. The machine software calculates the optimum utilization of the material between the defects. The considerably smaller proportion of residual pieces left over from this process is still fed into pellet production.

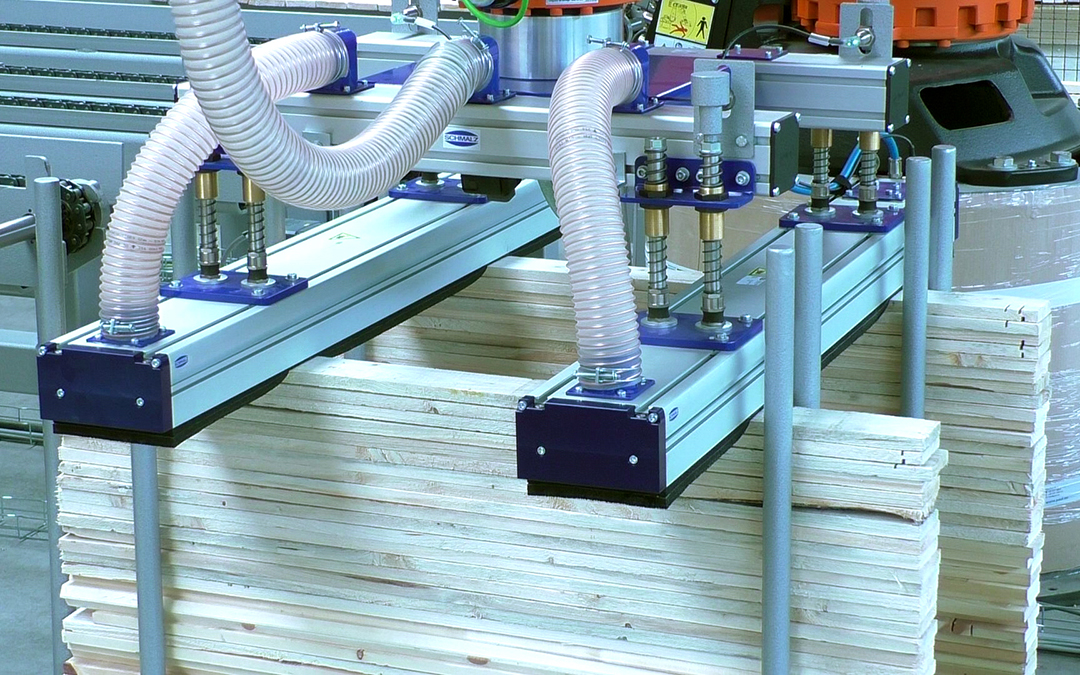

After the cutting process comes the sorting process. A 5-axis robot with a vacuum gripper stacks the workpieces according to width, thickness and length at one of four buffer stations. This means that the robot replaces up to four automatic stacking machines and can also insert stacking sticks between the layers, making it a very economical and flexible solution. The system automatically transports finished stacks to the position where they can be picked up by a stacker.

Paul was convincing in the project planning of the overall system as well as the production and programming of most of the individual components. By linking the robot control with the Paul MAXI control, the entire system can be conveniently operated via a terminal.

Many experts expect wood to become an increasingly scarce resource. The Paul team is pleased to be playing its part in the responsible use of raw material with the timely installation and commissioning of the optimizing system at Westerwälder.